TPA Smart Laboratory: Empowering Efficient Management of Automotive Electronics Testing!

Release time:

2025-07-23 14:51

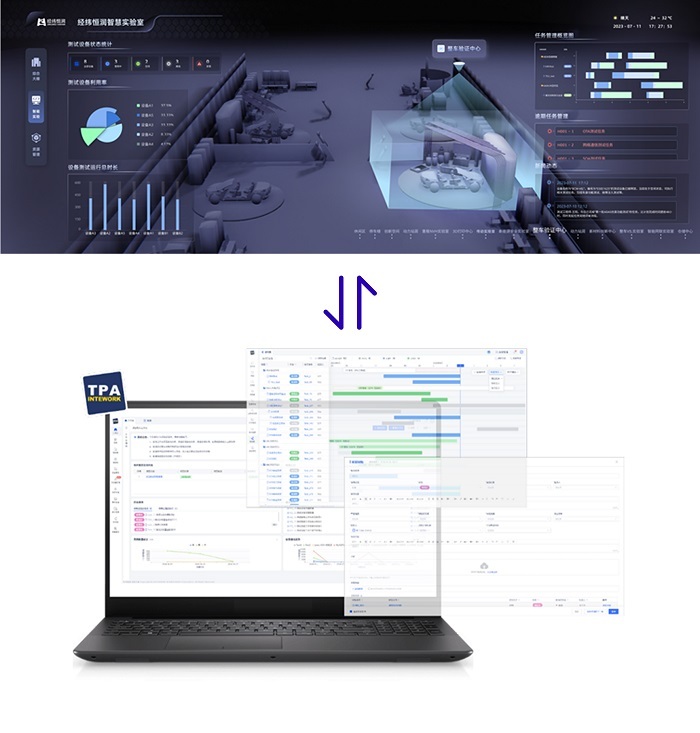

With the accelerated iteration of automotive electronic products and the increasing complexity of testing scenarios, traditional laboratories are facing challenges such as low automated testing rates and insufficient equipment utilization. To address management issues like heterogeneous device monitoring and cloud testing environment integration, HiRain has innovatively launched a Smart Laboratory Management Solution. It enables cross-regional collaborative testing through a remote test scheduling platform, breaks down information silos relying on data-driven technologies, and builds a digital twin laboratory with a visual dashboard, helping industry partners break through the efficiency bottlenecks in automotive electronics testing.

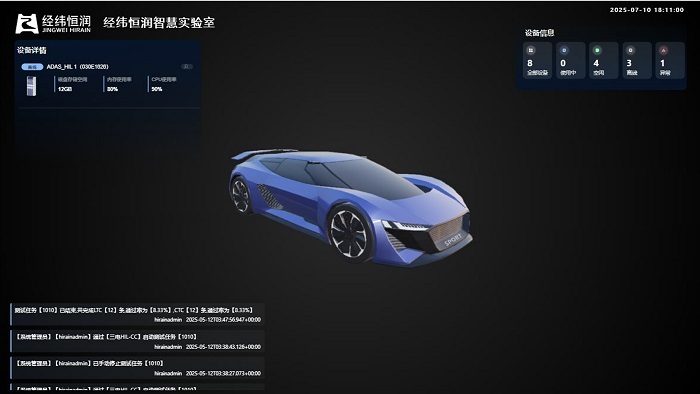

Cross-Platform Remote Testing: Contactless Equipment, Automated Execution

TPA can remotely access HiRain's self-developed TESTBASE series HIL simulation equipment, providing functions such as test case distribution, test sequence synchronization, remote scheduling and execution, and result report feedback, as well as parallel testing and intelligent scheduling strategies. At the same time, it supports access to data from other laboratories (such as bench laboratories, EMC laboratories, and other performance laboratories), realizing unified management of cross-laboratory equipment and improving the automated testing rate of new vehicle models R&D and the utilization rate of laboratory equipment.

Data-Driven: Breaking Isolation, Connecting Data

There are multi-source heterogeneous data in the laboratory, such as instrument data, experiment reports, and personnel information. In the past, these data were isolated from each other and difficult to exert value. The data source management of TPA's dashboard components integrates various data resources in the laboratory. Through standardized data interfaces and AI-assisted data analysis and processing, scattered data is collected. Whether it is massive experimental data generated by testing equipment or manually entered experimental records, they can be uniformly connected to form a complete data chain, providing a solid data foundation for laboratory management decisions.

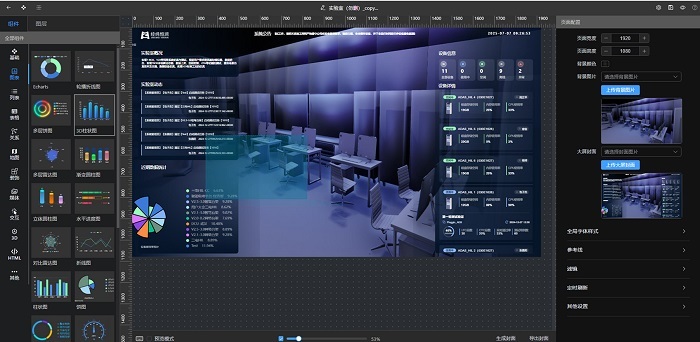

Visual Dashboard Construction: Say Goodbye to Customization, Build as Needed

The visual dashboard construction mode of TPA is like "Lego bricks" for laboratory management. Without complex code writing, the system provides more than 60 types of components such as 3D models of cabinets and benches, charts, maps, streaming media, and decorative effects. Engineers and managers can quickly build an exclusive laboratory management dashboard through dragging and simple configuration operations. This not only significantly shortens the dashboard construction cycle and reduces the cost of customized dashboards, but also allows engineers to easily participate in system construction and optimization, quickly respond to real data visualization needs, monitor the status of laboratory equipment in real time, and obtain information such as equipment operating parameters, usage duration, environmental status, test task execution, and test case result statistics.

3D Model Support: Digital Twin Empowers Dynamic Laboratory Monitoring

The dashboard components of TPA are pre-installed with common 3D models such as laboratory benches, cabinets, gateways, commercial vehicles, and passenger vehicles. It supports users to quickly layout based on actual laboratory equipment and topology. Based on the data-driven technical base, real-time data analysis results can drive the visual status effects of 3D models in the laboratory, such as the window lifting effect of the cockpit, realizing the linkage of original experimental data, target data processing results, 3D laboratory twin effects, business charts, and streaming media data.