Diagnostic system development consulting services

As the complexity of automotive electronic control systems and consumers' requirements for automotive after-sales services increase, the importance of diagnostic system development in vehicle development is becoming more and more prominent.

The goal of the diagnostic system development is: through the reasonable design of electronic control unit (ECU) diagnostic functions, the development of the vehicle end of line (EOL) configuration and testing requirements, the establishment of after-sales service system, to ensure the quality of the vehicle factory, speed up the production cycle, improve maintenance efficiency, and establishment a closed-loop feedback system of after-sales maintenance and product development, in order to improve product quality and customer satisfaction, and then enhance the value and competitiveness of products.

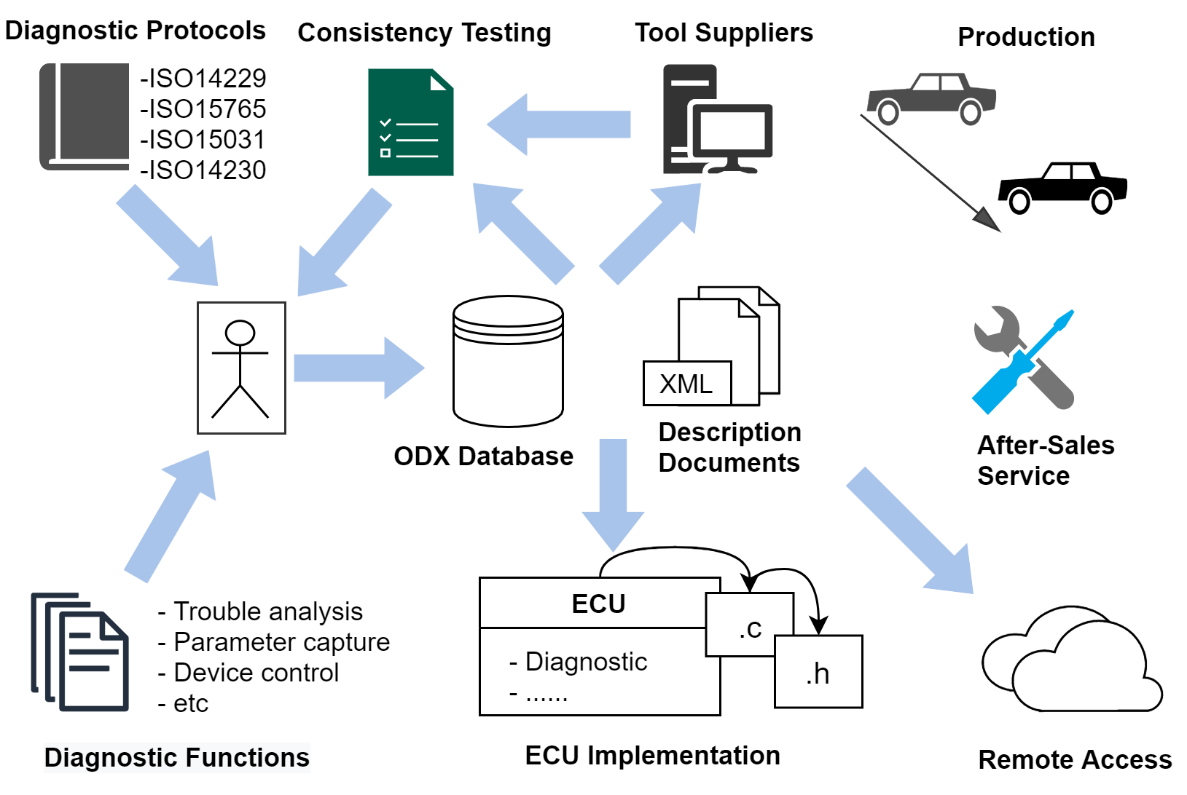

After years of practice, HiRain Technologies has accumulated rich experience, with business scope covering diagnostic protocol and function definition, diagnostic testing, EOL configuration and testing requirement design, vehicle after-sales diagnostic system planning, EOL and terminal diagnostic equipment development. The diagram below shows a vehicle diagnostic system with ODX (Open Diagnostic data eXchange) format as the data centre.

Vehicle diagnostic system

Service content

- Diagnostic protocol and function definition: with reference to the current international standards and mature technologies (ISO27145, ISO14229, ISO15765, ISO15031), combined with the vehicle manufacturer's own characteristics, develop platform-level diagnostic protocols to support trouble information reading, vehicle status identification acquisition, actuator debugging and reprogramming and other functions; based on ECU functional logic and electrical principle, define specific trouble information, identification data, debugging instructions, etc. to form component-level diagnostic specifications; create a standard diagnostic database (CDD or ODX) to ensure a seamless interface between OEMs and suppliers and shorten project development time.

- Diagnostic test: According to the test content, diagnostic test is divided into diagnostic protocol test and diagnostic function test. The former covers diagnostic service testing, reprogramming test, diagnostic logic test related to protocol. The latter covers trouble injection, identification information and debug instruction verification, etc. According to testing methods, diagnostic testing is divided into manual testing and automatic testing. The former is simple to implement and has low requirements for equipment, while the latter needs to be based on professional testing equipment and test scripts, but it can ensure the coverage of testing, improve the efficiency of testing and reduce the dependence of test results on engineers.

- EOL requirement design: Automated EOL configuration and testing function can quickly and comprehensively configure and test ECU functions. EOL requirement design includes the overall EOL process design, EOL configuration requirement (software download, electronic code, etc.) development, EOL testing requirement (part compliance, indicator, wiring harness connection, etc.) development, EOL equipment requirement development, etc.

- After-sales diagnostic system planning: Based on ECU diagnostic function, compile expert-level repair suggestions for vehicle and parts, form a standard database for integration with diagnostic equipment; develop after-sales diagnostic equipment requirements; design fault analysis and vehicle maintenance information tracking system to facilitate unified management of sold vehicles and provide feedback information for subsequent product development.

- EOL and diagnostic equipment development: Referring to the equipment development requirements and ECU diagnostic specifications, develop terminal equipment for ECU function configuration, electrical detection, trouble reading, vehicle status acquisition and online software update. These devices are developed on PC-based operating systems and offer a rich, user-friendly human-machine interface.

Service advantages

- Extensive experience: HiRain Technologies has participated in many development projects of electronic and electrical systems and diagnostic equipment for vehicles, and has a lot of ECU development and supporting experience.

- Comprehensive solutions: HiRain Technologies provides complete solutions, not only provides development services, but also provides testing services; not only implements requirement formulation, but also implements equipment development.

- Broad vision: HiRain Technologies participates in many vehicle development and testing projects, and defines the diagnostic strategy, EOL and after-sale requirements and component diagnostic functions from the system perspective.

- Considerate service: HiRain Technologies combines the organization structure and technical characteristics of vehicle manufacturers to provide professional and considerate local services.

Tel.:+86-10-64840808

Email:market_dept@hirain.com